We deliver a one-stop solution for your steel casting services need based on engineering drawings and information provided by clients.

Our Steel Casting services

We strive to deliver quality, precision products in a clear timeframe.

- Planning. We start with communicating with a potential client discussing on all parameters to account for best design solution and cost.

- Material selection and sourcing. Material options will be matched with the performance requirement of a part. We will use industrial standard and scientific papers to assist our selection.

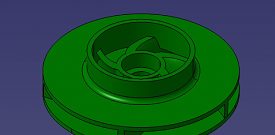

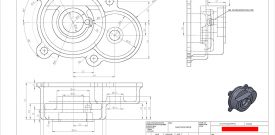

- Pattern development. Design process for precision pattern development start with accurate CAD model. We use Solidworks as our design tools. During pattern development we can simulate melt flow pattern using ProCast.

- Prototyping. First melt pour will become our initial prototype. We send initial product samples to ensure satisfaction before moving to formal production.

- Production. We supervise all manufacturing process and logistic.

- Heat treatment. Our services include a range of heat treatments for performance-specific applications. Steel often benefits from treatments that may include tempering, annealing, stress relief, case hardening, precipitation strengthening and quenching.

- Secondary processing. Additional processing may include machining, coatings and/or assembly.

- Packaging. Products are prepared and packaged to account for transport and storage.

- Shipping and warehousing. We arrange delivery to a specified location. Warehousing services may also be available.

- Import logistics. We take into account all costs and associated risks when arranging cross-border shipping.

- Quality assurance. We establish onsite manufacturing standards and conduct our own quality assurance to ensure accurate specifications.

Our quality control follows recognised industrial standards such as ASTM, JIS and ISO-EN which covers alloys’ chemical compositions, mechanical properties, metallographic analyses, Non-destructive test for casting defects and dimensional checks.